In almost all industries, heat is generated as a by-product of the production process. With Läckeby air-water heat exchangers, you make this excess heat or warm process air pay for itself.

Reusing heat is one of the most cost-effective and environmentally friendly investments available today. We offer robust and modular heat exchanger solutions with an excellent price/quality ratio. Our heat exchangers can be fully customized and integrated in your production process.

Air/water heat exchanger

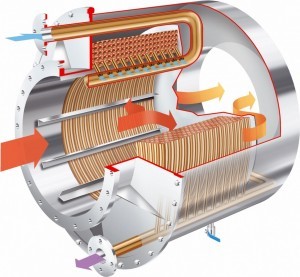

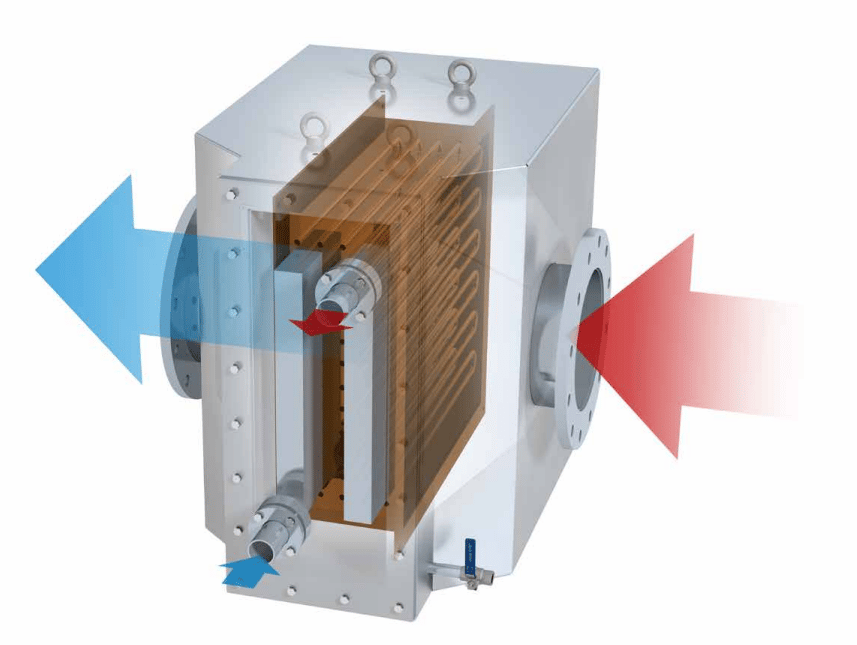

The air/water heat exchanger from Läckeby was originally designed to protect the membranes used in water treatment plants and extend their life. The heat exchanger was designed to efficiently reduce the temperature of the air passing through the membranes. Over the years, the realization has grown that this unique product is also perfectly suited to recover heat from air flows coming from blowers. Moreover, it is also very suitable for heating ventilation air or low pressure water circuits (more information).

The compressed hot air circulates freely between a closed circuit consisting of a large number of copper tubes containing coolant. This allows a high content of heat to be recovered from the incoming hot air stream.

How does an air water heat exchanger work?

Case studies

Our air-water and sludge-water heat exchangers are ideally suited for preheating water circuits. This pre-heated water can be used internally. For example, water treatment in laundries or other industries where large amounts of hot water are required.

More information about our sludge-water and sludge-sludge heat exchangers.

Why choose for Läckeby heat exchangers?

Läckeby heat exchangers are very versatile, you can also use them as cost-saving applications for air conditioning or heating.