Water treatment for industrial and agro-industrial purposes, water reuse and process water treatment

Task is disposing over more than 30 years of experience in the field of wastewater treatment.

For each project, a custom-made solution is offered with the best price-quality ratio. For each project, we select the most economic and the most suitable equipment according to the customer’s specific needs and requirements.

Task also supplies industrial water treatment equipment : jet aerations, flotations, dosing skids, agitators, floculators, coagulators, polymer production units, several types of oil separators, etc.

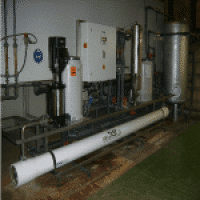

In the field of industrial wastewater treatment, Task is focusing on physicochemical wastewater treatment plants, membrane techniques (UF-NF,RO), water reuse, neutralizations, deferrizations, oil separations units from process tanks, jet aeration and sludge treatment.

- physicochemical wastewater treatment

- jet aeration

- oil separation – separation of oil – water emulsions

- NH3 strippers (stripping towers) – absorbers

- agitators

- Roto-Sieve rotary drums creens

- polymer production units

- neutralization units

- membrane technology – process water

- water recycling and reuse

- sludge treatment

- maintenance-retrofitting-optimization

According to the customer’s needs we build turn-key plants, we take care of the complete retrofitting and/or optimization of your existing wastewater treatment installation; we are also available for consultancy and engineering.

Optimisation and retrofitting of existing wastewater treatment plants

Lately we note an increasing interest amongst our customers for retrofitting and optimization of existing wastewater treatment plants. Customers having opted in the past for a low cost installation, have seen during the years that the installation doesn’t function properly any longer or that the installation can’t cope with recent production capacity increases. We can optimize or competely renovate your existing installation. We offer a custom-made solution, meeting all the required standards and customer demands at the best possible price. Whenever feasible and/or desirable the best parts of an existing plant are reintegrated in the new plant.

Wastewater treatment plants – Integrated solutions

Task can offer the best possible solution, always aiming for an optimal price-quality ratio. Our installations are seamlessly integrated in the existing unique production circumstances. A Task installation is durable, maintenance friendly, correctly dimensioned, with flawless functioning. The customer’s maintenance personnel is always thoroughly instructed to assure a longterm trouble-free installation. If despite all our efforts a problem occurs, a quick intervention is always guaranteed.

Experience in wastewater and process water treatment treatment

A wide range of industries are or have been relying on our experience for the realization of wastewater and/or emission treatment installations.

- waste collection and processing industry

- food industry

- automobile industry

- textile industry

- pet food manufacturers

- pharmaceutical industry

- metal industry

- chemical/petrochemical industry

For all of these specialisations we can present the corresponding job references.

Our main areas of expertise

Circular water use: recycling rather than discharging turns out to be more economic!

Water is getting more and more expensive. Wastewater treatment is seen as a cost and a burden. It doesn’t have to be like this, there is a better, more efficient and more economic way.

Companies realize more and more that not only savings have to be done in the field of water and energy consumption, but also that a substantial part of the water used can be recycled, rather than sending it down the drain. The investment for a water recycling unit with RO (reverse osmosis) and UF (ultrafiltration) membrane techniques can be earned back rather quickly. This way process waters can be upgraded to fresh process waters for reuse in the production process. But it is also possible to upgrade wastewater, after pretreatment to potable water.

Please have a look at our water reuse page, for more information. And, of course, it’s also possible to recover the energy of hot wastewater and highly viscuous sludge, for reuse elsewhere in the production process. Don’t let the money flow away any longer: recycle, reuse!