In water treatment plants and in biogas production plants, a lot of excess heat is created. Our sustainable sludge/sludge and sludge/water heat exchangers are specially designed to reuse this heat. As a result, the production cost is substantially reduced and the operational efficiency increased.

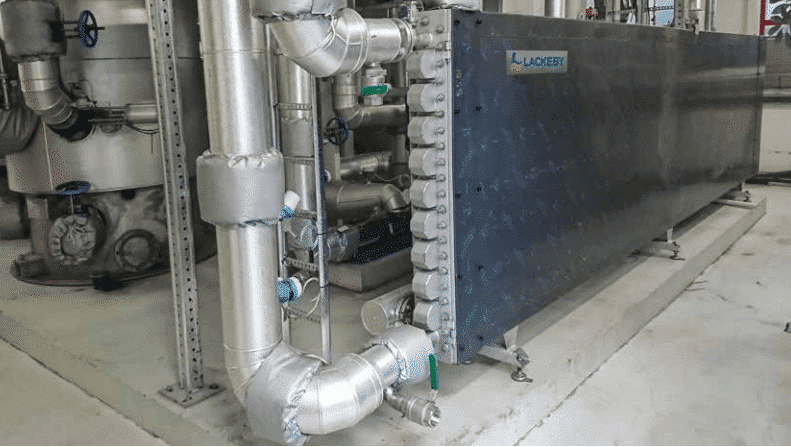

Task Environmental Engineering is your contact within the Benelux for the Läckeby range from Sweden. The high-quality Läckeby heat exchangers have been installed in water treatment plants and biogas plants for more than 20 years. These top-quality compact heat exchangers stand for a high degree of heat recovery, a long service life and easy maintenance.

Applications for heat exchangers

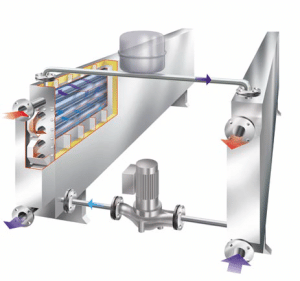

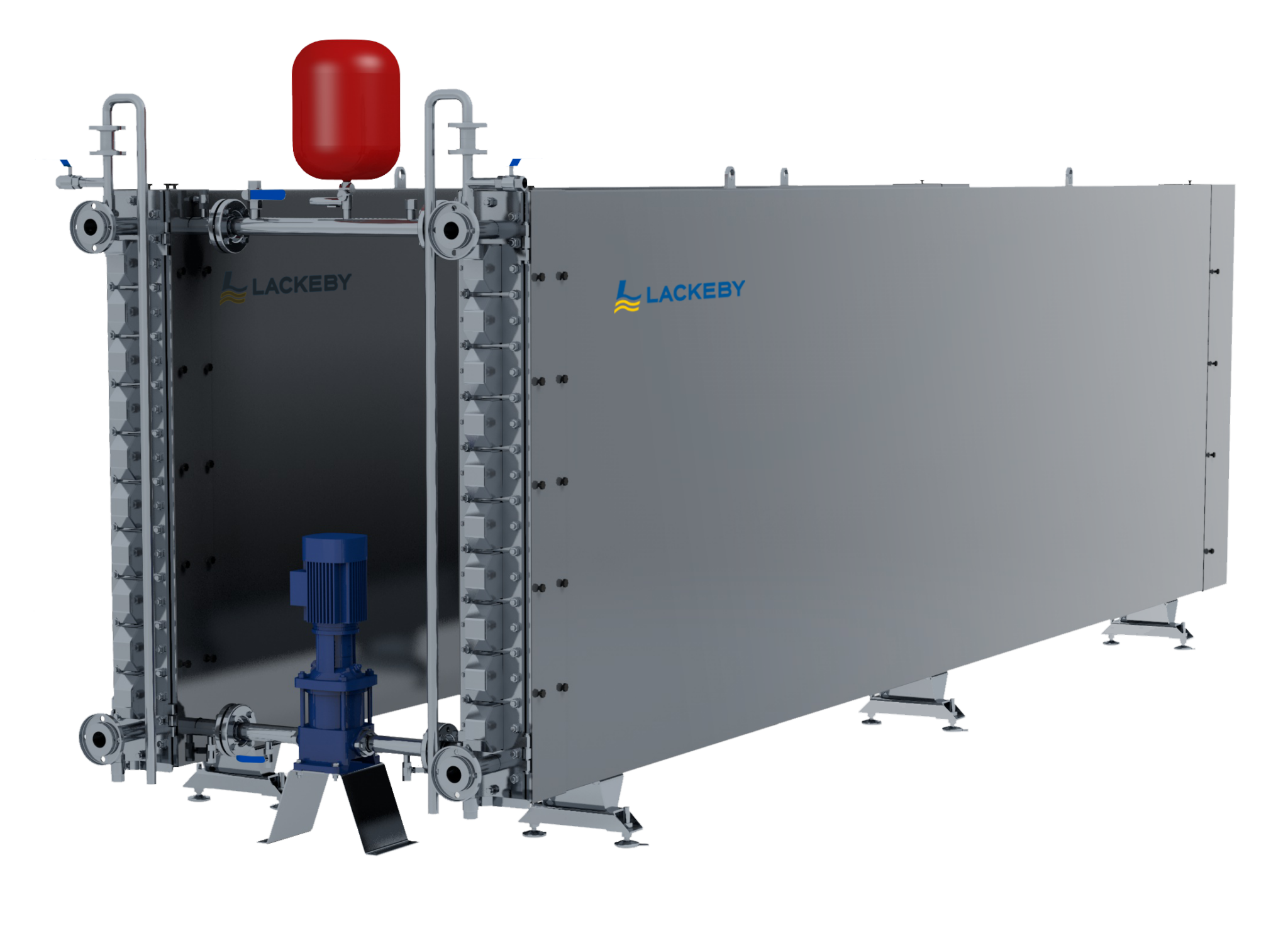

Our sludge heat exchangers are used for highly viscous substances, such as water treatment sludge and digestion sludge. They are compact units, clogging insensitive, have high heat transfer and large flow capacities. In addition, maintenance and inspection are very easy thanks to the hinged lids on the ends. Two versions are available: the sludge-water heat exchanger and the sludge-sludge heat exchanger. The sludge-sludge heat exchanger consists of two sludge-water heat exchangers, interconnected via the water circuit.

What distinguishes a Läckeby heat exchanger from other heat exchangers?

- Unique patented design especially for sludge

- High heat transfer

- Large flow capacity

- Minimal pressure loss

- Patented turning chamber facilitating quick inspection

- Clogging insensitive

- Compact (stackable) and easy to install units

- Homogenous sludge temperature thanks to good mixing in the turning chambers

- Insulated housing to prevent energy loss

- Extremely maintenance-friendly

How does a heat exchanger work?

Sludge applications

- direct heating or cooling of raw or digested sludge on the feed line

- heating or cooling of digested sludge or pasteurisation

- energy recovery from hot sludge

- agro-industrial digesters

- organic waste digesters

- biogas recovery from landfills

Wastewater applications

- cooling of wastewater in biological water treatment

- energy recovery from wastewater before discharge

- biogas production from sewage

- industrial wastewater treatment plants

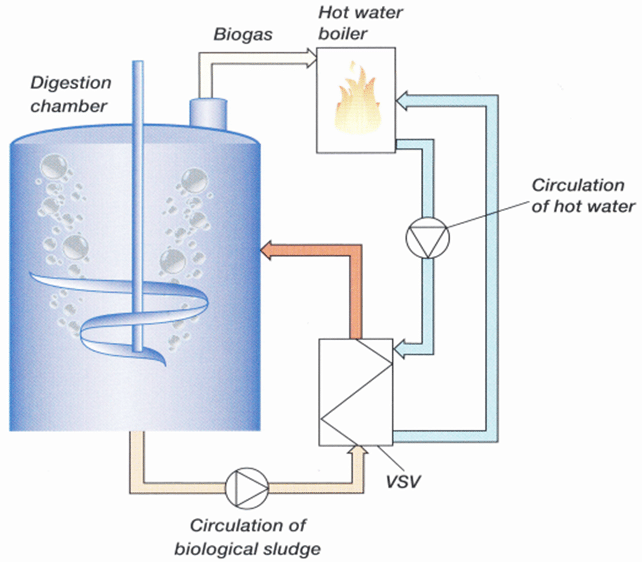

Heating the digester substrate in biogas plants

Our sludge/water heat exchanger is ideally suited for heating the digester substrate in anaerobic digesters (biogas). In this case, heat is extracted from central heating water to heat the sludge in the digester. These heat exchangers have been used with proven effectiveness in numerous large and small biogas plants.

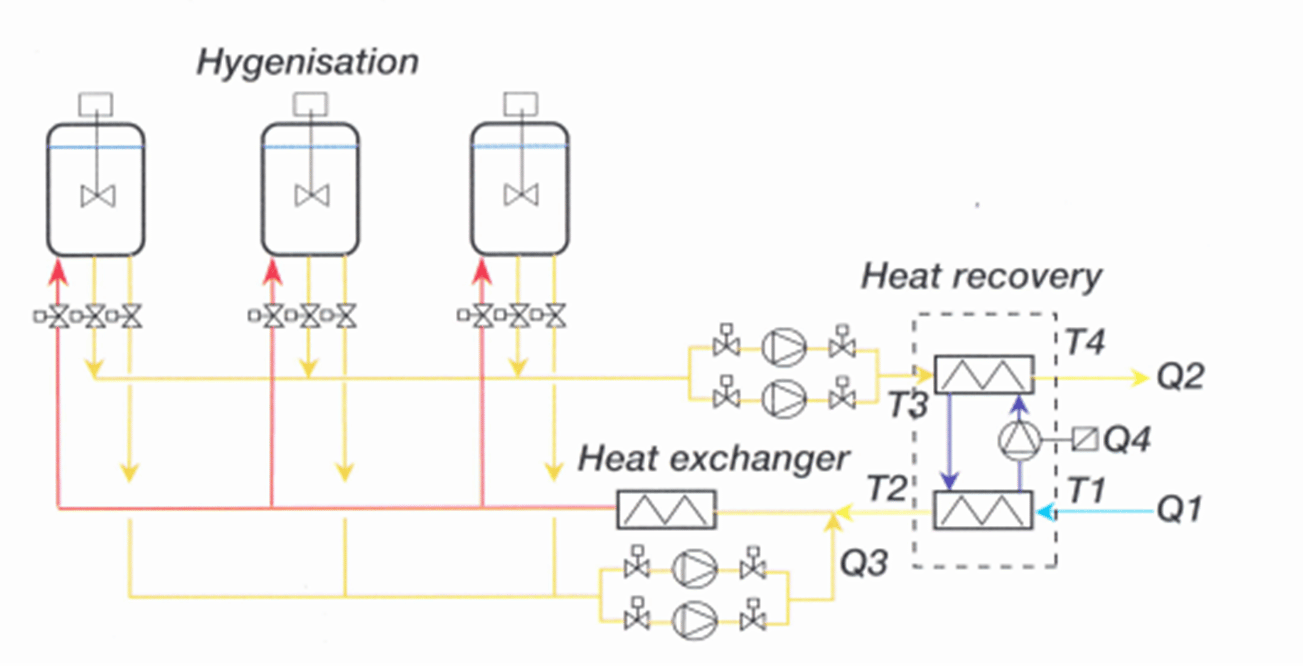

One step further: recover heat from digested sludge

The excess heat produced during the digestion process can be used to preheat the biogas substrate. The sludge/sludge heat exchanger recovers heat from digested sludge to release it to the raw sludge, through a closed water supply system. Such a design eliminates the risk of contamination.

An additional circular sludge-water heat exchanger can be used to keep the digester at temperature.

Preheating hot water circuits

Our sludge-water and air-water heat exchangers are ideally suited for preheating water circuits. This preheated water can be used internally. For example, water treatment in laundries or other industries where large quantities of hot water are needed.

Läckeby’s heat exchangers are very versatile, you can also use them as cost-saving applications for air conditioning or heating.

Custom made solutions

Task/Lackeby Sweden produce and install all necessary infrastructure to make your heat exchanger installation as performant as possible. Our heat exchangers are fully customised for seamless integration into your production process. The installation can be designed as a complete turnkey unit or you can choose to integrate the heat exchanger by yourself. Furthermore, we offer you a complete range of shaftless screw conveyors, shaftless piston presses and septic receiving units.

Installation and maintenance of heat exchangers

We provide efficient delivery and installation of each heat exchanger. You can also always contact us for the following services:

- Measurement and control techniques

- Technical assistance

- Upgrading and extension of the installation

Brochures

Projects heat exchangers

A selection of our realisations worldwide. Some projects were realised by the mother house Läckeby Sweden, some by our colleagues on all continents, some by Task. A click on the pictures below is providing more information about the projects.