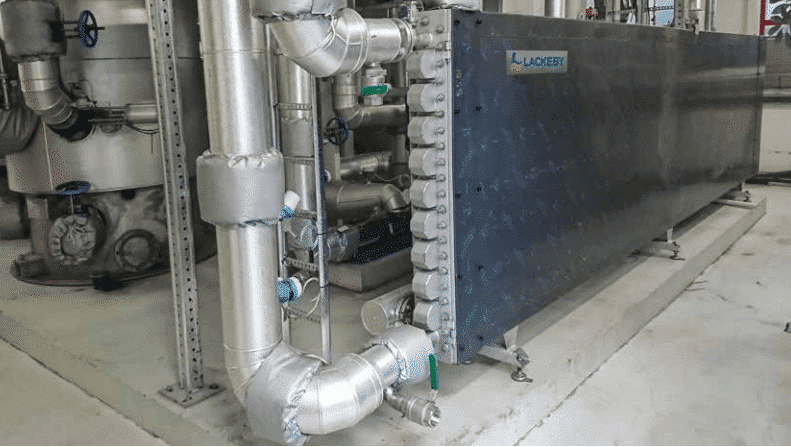

Lackeby heat exchangers for energy recovery

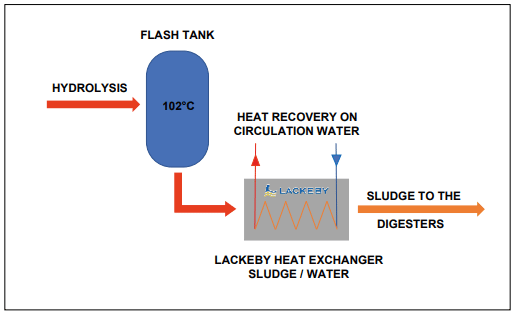

Energy recovery from thermal pressure hydrolysis

The incoming raw sludge is not sterile. As a result, the first step is hygienization or disinfection. Lindum A/S is using thermal pressure hydrolysis for this purpose (steam pressure heating). Therefore, the media are getting heated up to a minimum of 133°C, for 20 minutes. The maximum temperature is set to 160°C, requiring a pressure of 5-6 bar. Once the heating is finished, the temperature is to be reduced quickly to 40°C. This quick temeperature reduction is breaking down the cell structure and fibers to smaller particles. In other words, the thermal pressure hydrolysis process assures a quicker and more efficient break down of structures difficult to digest by bacteria. Organic material gets digested better and quicker this way. The installation of the Läckeby sludge-water heat exchanger has contributed to an efficient and cost-saving thermal pressure hydrolysis process.

Circular solutions in the green economy

Lindum A/S is one of the major players in Norway in the area of waste collection and waste processing. Lindum A/S is constantly searching for green solutions and technologies to reuse as much as possible of the waste collected and processed. For example, Lindum is producing biogas from manure, sludge and household waste. Lindum is spending a lot of time and money on their search for green solutions and is proud to play a main role in Norway’s cricular economy.

The Lackeby solution

In 2016, Läckeby was contacted by Lars Erik Smith from COWI, a leading norvegian company, active in the field of construction, environment, energy and infrastructure. It was Covi’s task to find a solution to firstly use existing process water as cooling medium for the sludge. And secondly reuse the heated water back into the process. As the available process water was not as cold as first expected and seen a limited space in the Lindum facilites, Läckeby wasn’t able to reach the requested 40°C in one step. On the other hand, we got much closer than what Covi had calculated from the start. After cooling, the sludge gets mixed with water before entering the digester tank, allowing us to reach the requested 40 °C temperature.