Läckeby Roto-Sieve® drum screen are always performant in highly demanding production processes

Wood pellets production : Bioenergi in Luleå, Sweden

Bioenergi in Luleå started manufacturing wood pellets in 1998. Today, it is one of the biggest pellet manufacturers in Sweden. The production capacity is about 95.000 tons of pellets/year. This state-of-the-art pellet manufacturer is located in the Aronstorps industrial area in Luleå, close to the SSAB steel factory. With only 17 employees, Bioenergi is running one of the most advanced pellet manufacturing facilities in Europe.

In the past, Bioenergi was using a decanter-centrifuge to separate and dewater wood fibers from the cooling water. This cooling water was used in the scrubber. It is common practice in the wood pellets business to install a centrifuge on the cooling water circuit. However, the disadvantage of this system is the high energy consumption and the high maintenance demands. As maintenance cost increased once more, managing director Conny Holmberg started actively looking for a solution. This new solution had to be efficient and priceworthy.

Discovering Roto-Sieve rotary drum screen

Whilst visiting Lantmännen Agroenergi in Ulricehamn, nowadays known as Scandbio Ulricehamn, the Läckeby Roto-Sieve equipment caught his eye. Läntmannen Agroenergi had recently replaced its Rotopass sieve by a Lackeby Roto-Sieve® drum screen model RS 24. This turned out to be an uncomplicated and reliable solution. And this was exactly what Managing Director Conny Holmberg was looking for. After going through some general references, he decided to purchase Lackeby’s equipment. He choose a Lackeby Roto-Sieve® drum screen with a Lackeby Screw conveyor press. “Since we also have some lye in the effluent, we have chosen the acid-proof stainless steel 1.4404 version”, Conny explains.

A hot gas closed loop circuit

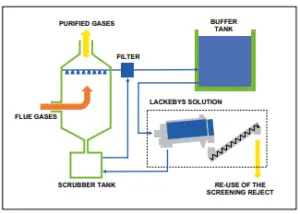

From the SSAB steel factory in the neighbourhood, hot process gas pipelines first lead to the Lulekraft powerplant, where large quantities of energy are recovered from this hot gas. From the Lulekraft power plant, the 450°C process gas is directed to the big drying drum at Bioenergi. There, the hot oxygen-free gas dries the pellets. The gas then flows into a cooling scrubber. This cooling scrubber is cooling down the gas temperature from 450°C to 90°C, over just a few meters. During the drying process, the hot gas is collecting wood dust and wood particles, all ending up in the cooling water.Roto-Sieve for the separation and dewatering of wood particles

As we are talking about a closed loop system, this material needs to be filtered out. And this is where the Lackeby Roto-Sieve® drum screen will be able to demonstrate its usefulness. At the outlet of the Roto-Sieve drum screen the water has a temperature of about 60°C, before it gets directed back to the closed system. The removed wood particles get further dewatered with a Lackeby Screw conveyor press model SCP 220. Then they get redirected to the closed loop production system, to be transformed into wood pellets.Result: closed loop system – full circularity

After one year in operation, operations manager Fredrik Nilsson is happy to conclude that the decision to install a Läckeby Roto-Sieve drum screen was a good one. “Initially, we used a drum screen perforation of 1,25 mm. But, it was after changing this into a 1,0 mm drum screen perforation, that we have found the optimal solution”, says Fredrik. Being operations manager, Fredrik appreciates the uncomplicated and easy accessible design of the Roto-Sieve. In addition, there is another very positive fact. That is that Läckeby’s solution only consumes 20% of the energy consumption of the old centrifuge. Conny explains that the water flow rate over the scrubber is about 10 m3/h. The amount of recovered wood fibers is about 100-150 kg. And this with a DS (dry solids content) of 25-30 %, after dewatering.

Close customer – supplier collaboration for an optimal result

At the time of the Läckeby Roto-Sieve® drum screen installation at Luleå Bioenergi and Agroenergi in Ulricehamn there was no experience. The concept and use of a Roto-Sieve drum screen in a wood pellet production plant was previously untested. Nor the customer, nor Läckeby had any experience with this kind of application. As a result, at that time, we couldn’t present any references.

Roto-Sieve rotary drum screen for sticky substances

Läckeby has manufactured drum screens since the 1960’s and has delivered more than 5000 units throughout the world meanwhile, but never before to a wood pellets manufacturer. Initially, there were some problems. But, after having made some adaptations to meet the very specific and challenging demands of a wood pellets factory, we came to a good solution. The combination of high temperature and material with high content of sticky substances such as resin, led to a special Roto-Sieve drum screen design, that both Bioenergi in Luleå and Scandbio’s pellets factory in Kammarp are now using with good results.

“Our goal is to continuously improve and develop our production. The implementation of Lackeby’s solution is a step in the right direction. It was an excellent decision to replace the centrifuge”, says Conny Holmberg, Managing Director Bioenergi i Luleå AB.

Result-oriented approach

Task and Läckeby do not only supply equipment, we also like to think along with the customer, to find an optimal and custom-made solution for each project. Together, we obtain the best solution for high performance and cost-effective production and treatment processes. Most importantly, this allows you to focus on your business. It is not necessary having to worry about equipment failure and all too frequent maintenance services.

More information on our Roto-Sieve rotary drum screens.