Are you looking for the best sieving technique for wastewater? Roto-Sieve® rotary drum screen are used in the primary stage of wastewater treatment and process water treatment to separate solids and fibres from liquids. Sticky or greasy particles are also no problem for these drum screens! For the sieving of septage, we offer special septic receiving units.

Rotary drum screen Roto-Sieve for water and wastewater treatment

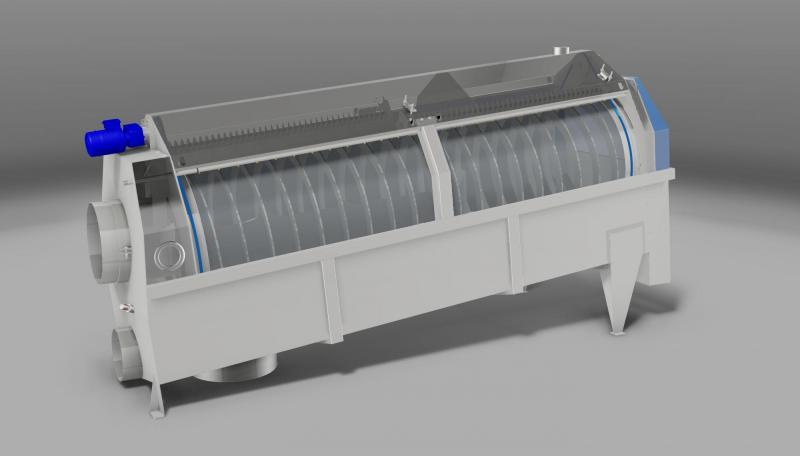

Roto-Sieve is a rotary drum screen or sieve, with internal feed, slightly inclined drum and round perforations. This results in the best possible mechanical separation. Round perforations hold fibres and hairs much better than slotted ones.

Läckeby AB (owner of Roto-Sieve) is a stable and reputable Swedish family business, founded in 1935. Today, the third generation, Magnus Axelsson, is at the head of the company.

By the way, did you know that all wear and spare parts are always available from stock? Even for Roto-Sieves older than 30 years! Sustainable design saves working hours and contributes to a circular economy.

We at Task do not avoid any question, we can also have a look at your current screening process to improve its efficiency. Our long-standing experience in water treatment and sieving techniques at your service.

Why choose a Roto-sieve® drum screen?

- self-cleaning, so minimal maintenance

- high operational reliability

- compact unit

- high separation efficiency

- long service life (20+ years)

- fully closed system, no odour nuisance

- easy to install and operate

- internal power supply (gravitationally or with pump)

- low energy consumption

- wide range of capacities (5 to 1,000 m³/h)

- advanced drive system, no trunnion wheels

- lightweight covers for easy and quick access to the sieve drum

- lowest number of moving and wearing parts on the market

- all spare and wear parts are easy to replace.

- No complicated metal chain drive systems, so no automatic lubrication is required

- Best buy, expressed in cost per year of life

References in all kinds of industries worldwide

There are already 5300+ Roto-Sieve® drum screens in operation worldwide. Roto-Sieve rotary drum screens are used successfully in numerous industries (water purification and water treatment).

- Breweries, malting plants & bottling plants

- Municipal and urban sewage treatment plants (WWTPs and KWZI)

- drinking water production

- shipping industry and shipyards

- dredging

- textile industry

- feed production, pet food

- slaughterhouses (cattle, poultry, etc.) & offal processing

- recycling companies

- plastic

- paper

- oil

- pumping stations

- fat melting

- tanneries

- chemical industry

- food industry and semi-finished food products (sugar, fish, dairy products, etc.)

- vegetable and fruit processing industry (e.g. potato)

- coffee roasting

Customised Roto-Sieve® rotating sieve

Roto-Sieve rotary screens are produced in five different models for different water flow rates. Available materials for the drum screens are stainless and acid-resistant steel. All models are equipped with lightweight glass fibre reinforced polyester splash guards. The brushes are made of a heat-resistant material. Standard screen perforations are 0.8-1.0-1.5-2.0-3.0 mm, the smallest available perforation is 0.6 mm. All models are supplied with an integrated emergency overflow (except model 11).

The best screening technique for your wastewater

Why choosing a drum screen rather than a bow sieve for the separation of solids and fibers? Aren’t they both doing the same thing?

Correct, in theory, but in practice there are substantial differences.

Our Roto-Sieve drum screen has a higher separation efficiency than a bow sieve. In addition, the internal feed makes flooding impossible. Roto-Sieve rotary drum screens have a standard integrated emergency overflow and are fitted with an emergency overflow detection and connection.

Important to know is that Roto-Sieve drum screens are completely closed units, so there is no odor nuisance. The self-cleaning function and sophisticated design assure low-maintenance. Furthermore, the design enables wear parts to be replaced quickly and efficiently.

Canal sieve versus drum sieve

Looking for performant screening? Roto-Sieve drum screen are more effective than channel sieves. A larger quantity of suspended matter is separated per unit of time compared to channel sieves, channel grids, step screens, etc.

In addition, the Roto-Sieve drum screen is not under pressure, so solids and fibres are not pressed through the perforations. This gentle treatment ensures that only particles smaller than the perforation can pass through. This is not the case with a channel sieve.

Roto-Sieve drum screens with integrated overflow detection give 100% certainty that all incoming water will pass over the perforated area. With channel screens, everything depends on whether or not there is an effective seal at the sides of the unit.

Efficiency and back-flush of screens: The internal spiral in the Roto-Sieve drum screen ensures that the screenings are gently and gradually transported to the outlet. With many channel sieves, the screenings are transported to the outlet with a brush. The brush often causes the screenings to be pushed back through the perforated openings. To finally end up into the canal with treated water.

Easy inspection and maintenance of your Roto-Sieve: The lightweight glass-fibre reinforced polyester covers of the Roto-Sieve provide a super-fast visual inspection of the sieve drum and easy access to all components. This can be done during operation: the entire production and water treatment process does not have to be stopped.

Canal sieves, on the other hand, are constantly under water during operation. As a result, there is absolutely no control of seals or proper operation. So, it is necessary to lift the entire unit out of the water for inspection and maintenance. It goes without saying that this operation takes a lot of time and effort. Moreover, in practice, checks are therefore usually only carried out when encountering problems.

Roto-Sieve spare parts service Benelux

There is a track record for every authentic Roto-Sieve drum screen and spare parts are available from stock for life. We can supply you with all spare parts for your existing rotary drum screen. Roto-Sieve drum screens are made to last. Spare parts for the Roto-Sieve units from the 80s and 90s are still available from stock.

Do it yourself or have our technicain come by

Spare parts are easy to replace and well accessible. On simple demand however, our technician can do a complete revision of your machine on site or install the spare and wear parts (entire Benelux). A single technician completes the job in no time, no need for cranes or other lifting equipment. Our Roto-Sieve network is always ready to provide assistance, on site or remotely.

Of course, the internal drum can also be repaired or replaced. If you want to use the machine for a different application within your company, you can opt for different drum perforation openings. An overview of Läckeby/Roto-Sieve distributors worldwide can be found here.

Task Environmental technologies is your distributor for new Roto-Sieve drum screens and spare parts for the Benelux. Give us a call, with your unique serial number or a picture of the machine tag at hand (10-xxxx): even if all manuals of your machine are lost, we can put you on the right track very quickly.

Projects

Below you can find a selection of our realisations worldwide. Some projects were realized in Scandinavia, some by our colleagues on all continents, some by Task. A click on the pictures below will give you more information on each projects, with pictures, films, etc. to clarify.

Roto-Sieve ®, a registered trade mark

Roto-Sieve is a registered trademark owned by Läckeby Products in Kalmar, Sweden. An authentic Roto-Sieve drum strainer carries an identification plate with all its details (the unique serial number – type – year of manufacture and original drum perforation). Manufacturer is Roto-Sieve AB or Läckeby Products AB from Sweden.